Special Features

- 2 operation modes:

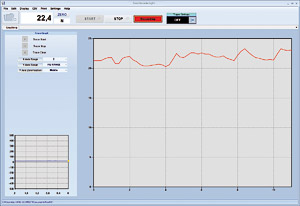

real time – display the actual tension or compression force

peak force – to measure the peak force during a test - Force gauge ZTS-DPU with extremely high sampling rate of 2000 times/sec for fast acquisition of peak values

- Display update time 16 times/sec

- Easy to read display (OLED)

- The header and footer of the display can be customized, as well as switched on and off

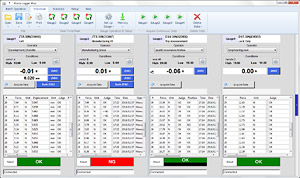

- Programmable high/low set-points for go/no-go testing:

with color-coded LED display: underrun (-NG) – good (OK) – exceeding (+NG) and relay outputs - Storage of 1000 values, which can be recalled:

– on the display

– data transfer to a PC

– for printing with report - Output signal:

– RS-232 C for connecting to a PC

– USB

– analog ±2 V DC - Display can be reversed for inverted use; e. g. on vertical test stand

- »Zero Set« to zero the gauge in all operating positions

- Alarm indication in display and output signal in case of overload for test stands of series MX, MX2 and EMX

- Force gauge ZTS-DPU with user switchable units: N, kgf (gf) and lbf (ozf)

- Selectable language (English, German, Italian, French, Spanish, Chinese, Japanese, Korean)

- Manufacturers inspection certificate is included

Standard Features

- Force gauge ZTS-DPU for exact measuring with an accuracy of ±0.2 % full scale

- Approx. 200 % overload protection

- For hand-held use or mounting on test stand

- Ergonomically-designed, rugged die-cast aluminium housing

- Non-slip rubber grip

- Operates on rechargeable battery and/or AC adapter

- Full set of accessories included

Available Models

| Model | Capacity N | Resolution | Capacity gf; kgf | Capacity ozf; lbf | Measuring shaft |

| ZTS-2-DPU | 0 – 2.000 N | 0.001 N | 0 – 200.0 gf | 0 – 7.00 ozf | M6 |

| ZTS-5-DPU | 0 – 5.000 N | 0.001 N | 0 – 500.0 gf | 0 – 18.00 ozf | M6 |

| ZTS-20-DPU | 0 – 20.00 N | 0.01 N | 0 – 2.000 kgf | 0 – 4.400 lbf | M6 |

| ZTS-50-DPU | 0 – 50.00 N | 0.01 N | 0 – 5.000 kgf | 0 – 11.00 lbf | M6 |

| ZTS-100-DPU | 0 – 100.0 N | 0.1 N | 0 – 10.00 kgf | 0 – 22.00 lbf | M6 |

| ZTS-200-DPU | 0 – 200.0 N | 0.1 N | 0 – 20.00 kgf | 0 – 44.00 lbf | M6 |

| ZTS-500-DPU | 0 – 500.0 N | 0.1 N | 0 – 50.00 kgf | 0 – 110.0 lbf | M6 |

| ZTS-1000-DPU | 0 – 1000 N | 1 N | 0 – 100.0 kgf | 0 – 220.0 lbf | M10 |

| ZTS-2000-DPU | 0 – 2000 N | 1 N | 0 – 200.0 kgf | 0 – 440.0 lbf | M10 |

| ZTS-5000-DPU | 0 – 5000 N | 1 N | 0 – 500.0 kgf | 0 – 1100.0 lbf | M10 |

| ZTS-10k-DPU* | 0 – 10 kN | 10 N | 0 – 1000.0 kgf | 0 – 2200.0 lbf | M18 female screw |

| ZTS-20k-DPU* | 0 – 20 kN | 10 N | 0 – 2000.0 kgf | 0 – 4400.0 lbf | M18 female screw |

*Note:

No attachment is included with model of measuring range 10 kN and higher. These models do not have measuring shaft, but there is a female thread in place of a measuring shaft.

USB cable approx. 1.5 m long, CD-ROM with USB-driver and software “Force Logger” for data transfer

USB cable approx. 1.5 m long, CD-ROM with USB-driver and software “Force Logger” for data transfer AC adapter for 100 – 240 V AC

AC adapter for 100 – 240 V AC Aluminium, M6, measuring range up to 100 N

Aluminium, M6, measuring range up to 100 N Aluminium, M6, Ø 13 mm, measuring range up to 100 N

Aluminium, M6, Ø 13 mm, measuring range up to 100 N Aluminium, M6, 85°, measuring range up to 100 N

Aluminium, M6, 85°, measuring range up to 100 N Aluminium, M6, 85°, measuring range up to 100 N

Aluminium, M6, 85°, measuring range up to 100 N Aluminium, M6, 90°, measuring range up to 100 N

Aluminium, M6, 90°, measuring range up to 100 N Aluminium, M6, 80 mm, measuring range up to 100 N

Aluminium, M6, 80 mm, measuring range up to 100 N Aluminium, M6, measuring range up to 100 N

Aluminium, M6, measuring range up to 100 N Aluminium, M6, measuring range up to 100 N

Aluminium, M6, measuring range up to 100 N Steel, M10

Steel, M10 Steel, M10, Ø 23 mm

Steel, M10, Ø 23 mm Steel, M10, 85°

Steel, M10, 85° Steel, M10, 85°

Steel, M10, 85° Steel, M10, 85°

Steel, M10, 85° Steel, M10, 100 mm long

Steel, M10, 100 mm long Software for data acquisition by USB output

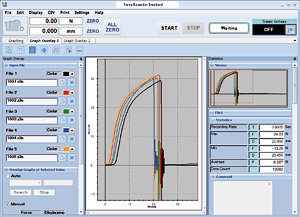

Software for data acquisition by USB output Additional functions in comparison to Force Recorder Light:

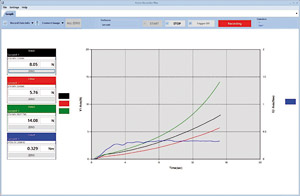

Additional functions in comparison to Force Recorder Light: Software for Data acquisition by USB output:

Software for Data acquisition by USB output: Software for Data acquisition by USB output:

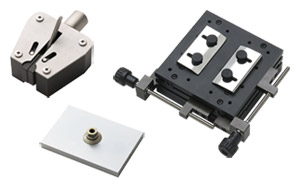

Software for Data acquisition by USB output: Depending on the application we have a lot of clamping tools and clamps for force gauge ZTS-DPU in our programm.

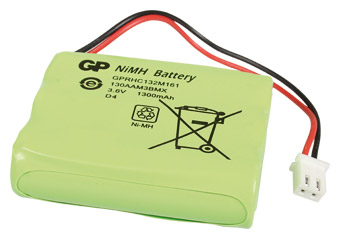

Depending on the application we have a lot of clamping tools and clamps for force gauge ZTS-DPU in our programm. Nickel metal hydride accumulator, 2-pole connector

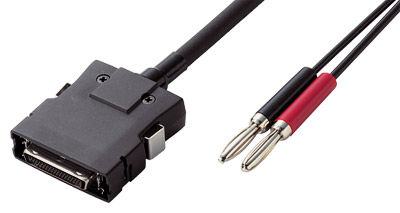

Nickel metal hydride accumulator, 2-pole connector Connecting cable for analog output, for connection to a line recorder.

Connecting cable for analog output, for connection to a line recorder. Connecting cable for RS-232 output with sub D 9 female, for connection to PC.

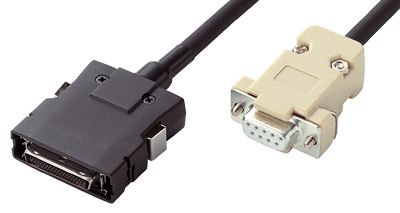

Connecting cable for RS-232 output with sub D 9 female, for connection to PC. Connecting cable for force gauge ZTS-DPU with test stand (Series MX) to stop feed at Fmax or overload (force control).

Connecting cable for force gauge ZTS-DPU with test stand (Series MX) to stop feed at Fmax or overload (force control). Connecting cable for force gauge ZTS-DPU with test stand (Series MX2 and EMX) to stop feed at Fmax or overload (force control).

Connecting cable for force gauge ZTS-DPU with test stand (Series MX2 and EMX) to stop feed at Fmax or overload (force control). Connecting cable for trigger input (input signal from an external device e. g. electronic switch to stop the measurement)

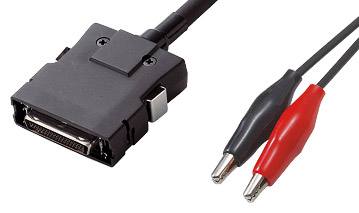

Connecting cable for trigger input (input signal from an external device e. g. electronic switch to stop the measurement) Connecting cable with open ends (37-pin) for all available output signals to connect an unique device.

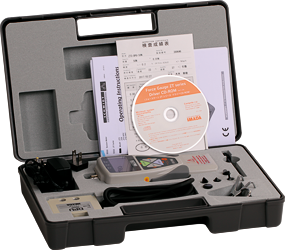

Connecting cable with open ends (37-pin) for all available output signals to connect an unique device. Indicator and separate force sensor with carrying case, standard accessories (depending on model),

Indicator and separate force sensor with carrying case, standard accessories (depending on model),